Maybe it’s information overload or just the campaign season blues, but lately I seem even more sensitive than usual to the constant presence of bullshit. Certainly the world of business seems carved from a solid block of it these days. Examples of “synergizing your dynamism” are everywhere, but it really pisses me off to be reading an otherwise good article only to see if slowly devolving into random spew.

A key aspect of LinkedIn seems to be keeping us all connected, not only to each other, but also to a steady parade of articles with interesting-looking titles that often have little or no value. Consider this otherwise interesting article “Five New Management Metrics You Need to Know” LinkedIn directed me to at Forbes. Overall, there’s some kernel of value in an article about more practical ways to monitor business health and performance, outside of just reviewing sales numbers, but this train comes off the track more than once. Written by Greylock Partners venture firm guy James Slavet, whose firm invested in Facebook, LinkedIn, Groupon, and Pandora, it becomes pretty obvious just how disconnected some of these people are from the daily functions of actual small business in America. Some of the article seems so rooted in bean bag chair Silicon Valley work-play as to be nonsensical to even the most ephemeral of businesses models–like “Metric 3: Meeting Promoter Score,” the idea that meetings should be evaluated to determine if they’re effective and worthwhile or not.

Most meetings suck. And they’re expensive: a one-hour meeting of six software engineers costs $1,000 at least. People who don’t have the authority to buy paperclips are allowed to call meetings every day that cost far more than that. Nobody tracks whether meetings are useful, or how they could get better. And all you have to do is ask.”

Gee, really? I guess my open mic meeting policy, where anyone could come in off the street and gather my key staff to talk about Tarantino’s Reservoir Dogs wasn’t the right way to do it. Thanks for clearing that up.

Certainly there are businesses in the world that allow idiots to call meetings that go nowhere, but do you really need to fill out a questionnaire afterward for management to realize the meeting was useless? If so, then this amazing common sense insight will be discarded anyway, because the manager is the idiot calling the unproductive meetings.

Then there’s this insightful observation about criticism and reward, or something, explained with a highly insightful analogy to marriage,

You can learn as much from John Gottman as you can from John F. Kennedy about being a great communicator. Gottman, a psychologist, is the author of “Why Marriages Succeed or Fail”.

In his research, he found that marriages that succeed tend to have five times as many positive interactions as negative ones. And when a couple falls below that ratio, their relationship falls down too.

The same is true at the office, where you’re often connected for years in relationships with people who can either become wary of your criticisms or eager to give you their best effort. Catch people doing good things. Never miss a chance to say something nice, even if you feel a little silly. Then when you have feedback on areas to improve, they‘ll really listen. It may be hard to manage to the 5:1 ratio at the office, but you should be mindful of the balance.”

First, having not read John Gottman, I have to hope he was somehow taken out of context here, though it’s hard to imagine how. So marriage partners who have more positive interactions tend to have better marriages? That’s some profound shit. Someone needs to tell the couples on the television show “Cops” that their marriages are in jeopardy.

And you’re supposed to “never miss a chance to say something nice, even if you feel a little silly.” Clearly someone needs to introduce Mr. Slavet to the term “patronizing,” which could have saved him a half dozen words, at least, thus increasing his productivity. Obviously, he’s not suggested being disingenuous, but glib shit like this dances over the actual work of management, which involves reading people and interacting with them honestly. This suggests a kind of golden mean ratio of compliments to criticisms, and adhering to that strictly would be as bad as administering only compliments or only criticism.

I made plenty of management mistakes running my own business, but if there’s one thing I did very right it was cultivate fierce loyalty, and I didn’t do it by telling people their hair looked nice.

In other business news more related to “doing” than “talking,” I think everyone who rides a mountain bike should try to design a bicycle suspension system. For one thing, you’ve probably done some bad things in your life, and this is one of the interesting methods of punishing yourself for past transgressions. That time you made fun of some other frame’s under-the-downtube water bottle position, or slightly high bottom bracket height? Trying to make your own will definitely pay you back for that.

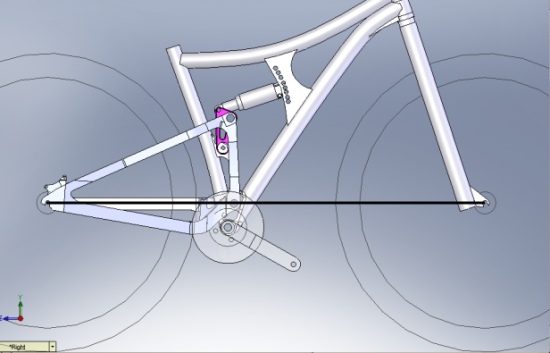

Given that I geek out on other designs even more than usual right now, I love that Ibis has posted photos and some text about the development of the upcoming Ripley 29er frame. What’s profoundly depressing for me in studying what Ibis did isn’t just how amazing their design aesthetic or business seems to be (though they’re all ‘o that), but rather this unsettling notion: I would have kept refining it.

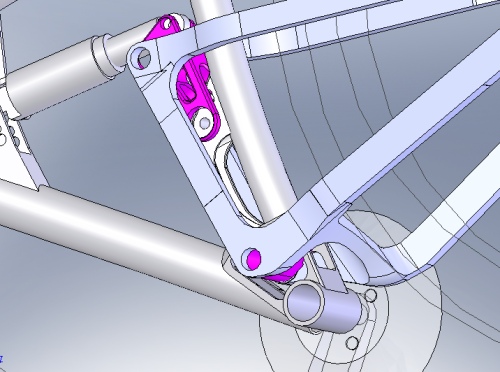

What the hell is wrong with me? Well, it isn’t the eccentric pivots that bother me–they aren’t that surprising to see more than one company now using, even though it’s tough to know what long term durability is going to be like. It’s the clevis, the structure that bolts directly to the shock and pivots off of the swingarm.

I love everything about the Ripley, and I love how Ibis sells and markets their products (they’re about as close to a micro-version of Apple as we get in the bike business), but even great marketing can’t take my eyes off the additional pivots on this frame. Sure, they’re not that big a deal, but why did you go to eccentrics if it tightened up your swingarm movement so much that you had to punt by delinking the shock? It seems even to go against Ibisinian design principles that have always embraced a “simplest design is probably the best” kind of aesthetic to introduce additional moving parts that have to be maintained. And it seems like an afterthought, which is weird. Ibis being Ibis and Dave Weagle being one of the only real thinkers in the entire bike business, they made great lemonade with that clevis by changing how it connects to the shock, which is great, but ask yourself how silly that piece would have looked if they hadn’t done that? You’d just be asking yourself, “Why didn’t they connect the shock directly to the swingarm?” I suspect they didn’t do that because they couldn’t, not because they didn’t want to, and that’s the only thing that bugs me about an otherwise amazing looking new frame.

Now somebody just needs to ride one.