Freakishly wonderful weather meant I put some time in on my Jones again today, and I had to chance to ride one of my favorite trails.

I’m aware of the irony of writing about designing a new full-suspension frame while spending time riding a rigid bike, but my trails are so perfectly smooth and obstacle-free that all those fancy pistons and ball bearings and such seem like decadent opulence. Why, once you’re out of the quarter mile rock garden on this section, you have only nine or so logs to hop before things mellow out onto a logging road. (“Logging road” is a local term, referring to rock gardens wide enough to try to drive a quad at least into if not necessarily out of.)

No, in all honestly, I was feeling pretty tired today and had planned on going with the Pivot 429, only to discover it had a flat front tire. I no longer work at a bike shop, which means every time I encounter even a small “mechanical,” I immediately give up and start looking for a different bike. So the Jones 1×10 got the call, and a damn good thing, too. Having rolled up on a 10-point buck entertaining his lady friend, I emerged unscathed and unintimidated, thanks to this.

Only four points, but they're titanium, so step off, Bambi.

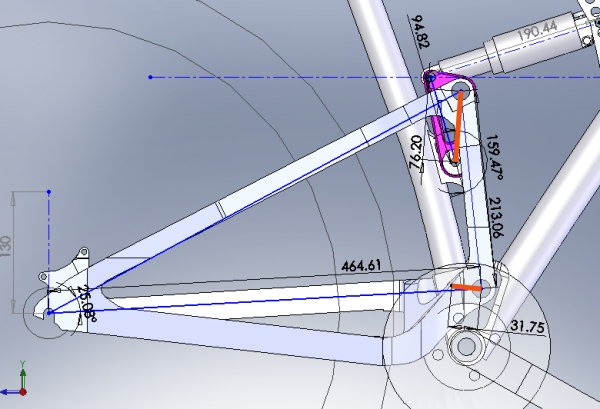

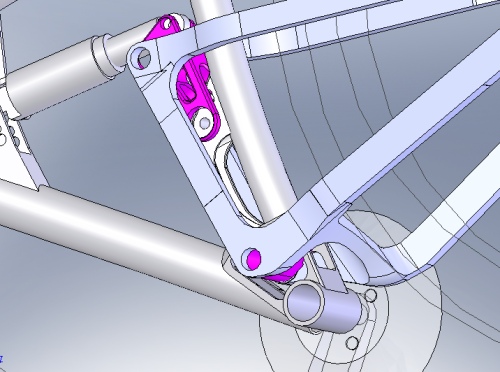

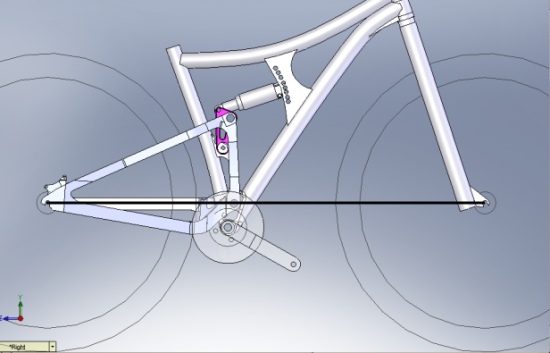

While gently coursing along, having the shit only lightly kicked out of me, I had time to contemplate the point of “full-suspension.” A friend following the suspension design stuff I’m working on recently asked me to write more about the basics of suspension–set up, how suspension is supposed to work on a mountain bike, that sort of thing. I’d been wondering where one begins something like that, and suddenly I had my answer.

The first step in understanding the basics of bicycle suspension is to ask yourself if you need it.

I don’t know a single hunter who uses an automatic weapon to bring home the venison. Assault rifles might be able to fire a hell of a lot more bullets at something, but that doesn’t make them “better.” Trying to use one would completely miss the point. But from what I can tell about preferred firearms for violent revolutions and zombie apocalypses, the more bullets, the better. Different strokes, you know. Consider, too, that I was living in Atlanta during the height of the SUV craze, and many of the vehicles being sold there were actually two-wheel-drive. As a guy who had to haul three dogs home to a particularly vertical part of Pennsylvania every winter and planned to move back there soon, I was looking for something a bit more four-wheel-drive, but the salesmen kept acting like I was requesting the humidor custom fitted to fit my favorite cigars option. He didn’t get why I would pay extra for powered front wheels. (In the end, we could only afford the powered front wheels of a comically small Saturn anyway.)

So my first piece of advice about owning a mountain bike with suspension is to ask yourself if you want it. Even the best full-suspension frames out there are more complicated than a rigid bike, and ask more of their owners. Maybe your trails are perfectly smooth (like mine), and you accidentally started a fire the last time you tried to change a lightbulb–in which case, the more enjoyable long term decision might be a bike with less going on.

There certainly seems to be a lot of simplicity going on these days. If you just dabble in the whole “mountain biking” thing, no doubt you’ve noticed that a lot of the cool guys have switched to brightly colored, really simple bikes and micro-brews with more complicated label graphics, instead of the previous vice versa.

This is because everyone else found out about full-suspension bikes, and owning one no longer says, “I’m deadly serious about this shit,” the way it used to.

They were riding full-suspension bikes when you were roller-blading, pal. Green Day isn’t a punk band. Welders’ hats are the new trucker hats. Marilyn Manson was just Skinny Puppy for slow kids. Handlebar mustaches are the new sideburns. Etc.

So maybe you don’t need a full-suspension frame for your riding, and you can get much nicer components for less money on a bike without suspension. With less to fiddle with, you might even ride more. It could be awesome.

But probably not.

For a lot of trails that aren’t as smooth and boring as mine, even a pretty compliant steel, titanium, or carbon frame that doesn’t have wheels that go up and down when they hit something is going to kick the living shit out of you every once in a while. Most owners of ultra-minimalist single-speeds also own suspension bikes, and the trade-off of lugging around the added weight and complexity sometimes means being able to walk the next day. It’s good to understand that–particularly with the rise of very slightly smoother-rolling 29ers–full-suspension bikes are no longer quite as aspirational–a marketing term that means “shit you want without knowing why,” but they still make a hell of a lot of sense.

So the first step to buying a full-suspension bike isn’t a technical detail or consumer check list: it’s asking yourself if you need one. You’re the expert there, and your favorite trails are your resource. They’ll tell you what type of bike to own, and whether you need a Jones H-bar, or an automatic weapon.