I’ve lost track of the hours I’ve put into Project Danzig, and probably best I did. But just when you think you’ve designed something pretty cool, a company in Japan comes along and releases giant robot that shoots people when you smile.

Lest that shot past you, let me just clarify that last sentence. One feature of the giant new armed robot being sold by Japanese killer robot makers, Suidobashi Heavy Industry–I mean aside from the fact that you can control it with an iPad–is that it shoots people in the face when you smile. Smiling operates the dual Gatling guns that fire BBs, so the funnier and funnier you find it that you’re using a giant robot to shoot your friend in the face, the more Kuratas shoots him in the face.

What type of insurance does a company like this buy?

Did I mention you can operate it from your smartphone? Of course you can.

Nothing I write about can possibly compare to the promotional video, though. Until you’ve watched an adorable Japanese girl’s demure giggles cause a robot to shoot someone in the face, you’ve never met the 21st Century.

My suspension design, in contrast, might one day make people smile, but that smiling won’t be able to put anyone’s eye out. At least not yet.

Clearly I have a lot of design work to do.

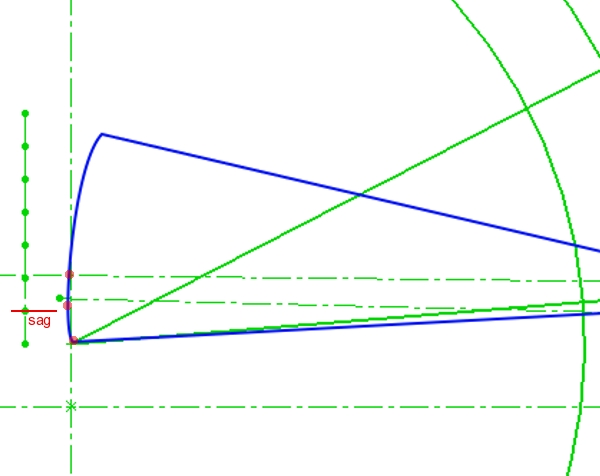

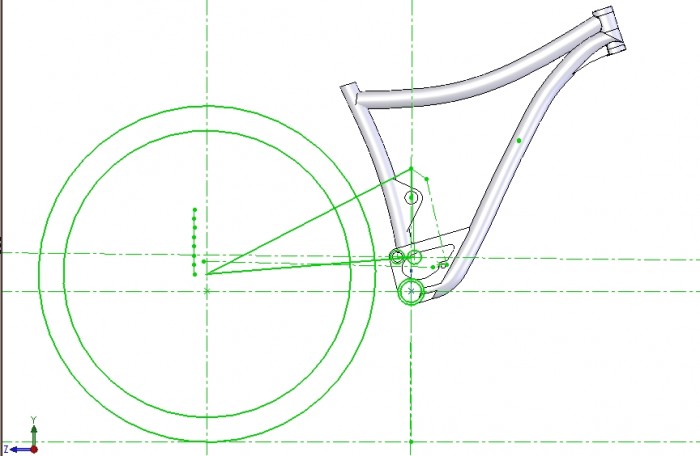

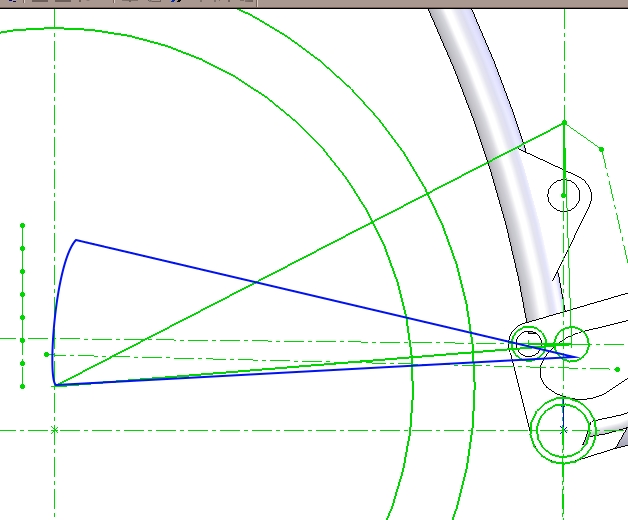

To that end, today we wrap up axle path–or the “versus propulsion” side of it. Here’s the drawing from yesterday.

The red dots mark three key stages of the axle path. If you look at the green vertical line along which the red dots are arranged, you’ll notice the lowest dot–which represents the bike sitting there with no weight on it–begins on the right hand side of the vertical line. As the bike moves up to its sag point, the axle moves to the left of the vertical line. The key is that the axle path continues to move rearward for 10mm of vertical travel beyond the sag point.

The idea is that chain tension continues to counteract the suspension’s movement until you’re 10-15mm beyond the sag point. The sag point is where the suspension stays when you’re riding around. Chain force hinders suspension movement until you’re 10-15mm beyond the sag point. Once you compress the suspension beyond that point chain tension no longer tries to control the suspension.

So that’s the idea. Almost all suspension bikes work this way, so I’ve not created anything unique there. What I did try to do, though, is develop a platform that will allow a huge range of options with all of these points. The system makes it easy to fine tune every aspect of the axle path.

So that’s what we’re going to do.

Responses to my “How much more would you pay for U.S.-made carbon fiber?” question keep coming in, but at this point the clear winner is $250-$500 more. The majority of respondents would pay up to $500 more for a carbon fiber frame if it were made in the U.S. Impossible to say how accurate that admittedly highly unscientific analysis really is, those are the results. I’ll keep an eye on incoming responses, though, because these things can change.

And maybe next week we ask how much more you’d pay for a giant killer robot that was made in the U.S. Makes me smile just thinking about it.