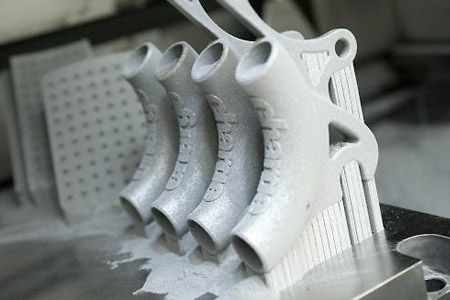

I think the 3D printed layers of titanium thing Charge is up to is just plain great. I’m also glad Bikerumor posted it, because I would definitely have missed it. Charge makes some pretty cool bikes, but I wouldn’t have expected the next stage of bicycle frame production to happen on their watch.

But this is it.

When I first starting working on a frame design back in 2007, I got to spend some time with an engineer who was developing vehicles for the military. The things she was helping to create were incredible, but the materials she was describing were off the charts. Their fabrication process sounded like carbon fiber, but they were metal. What’s going on in Charge’s video bares a strong resemblance to what she was describing.

Combined with an increasing realization that America has to wake up when it comes to manufacturing, these entirely new ways of creating bike frames are pretty interesting. Will you be manufacturing your own frame with an in-home 3D printer in the next few years? No chance. But things are changing.

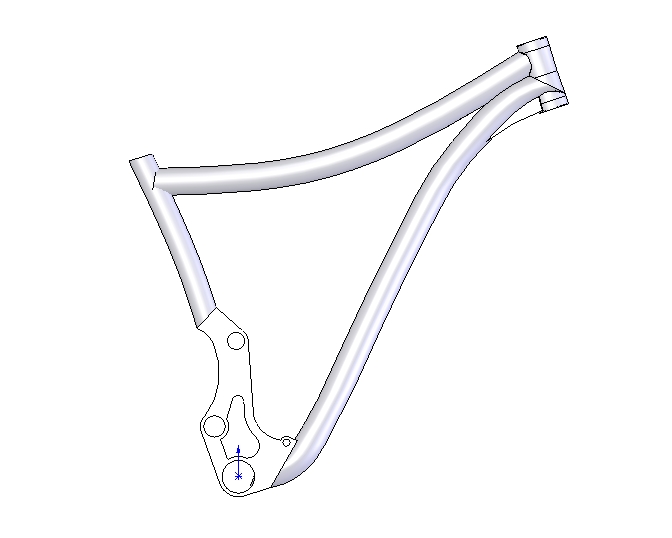

It occurred to me today that there might be some shorter distances between points yet on Danzig, and that I just might’ve been a little too conservative with the amount of tubing. If you’re going to have to machine something anyway, I think there’s a real benefit to putting all your pivots onto the same piece. Might change my mind once I see the price tag for machining that section, but here’s the last shot of Danzig’s main triangle for a while. Have to put some more time into the meetings necessary to bring this thing to life.